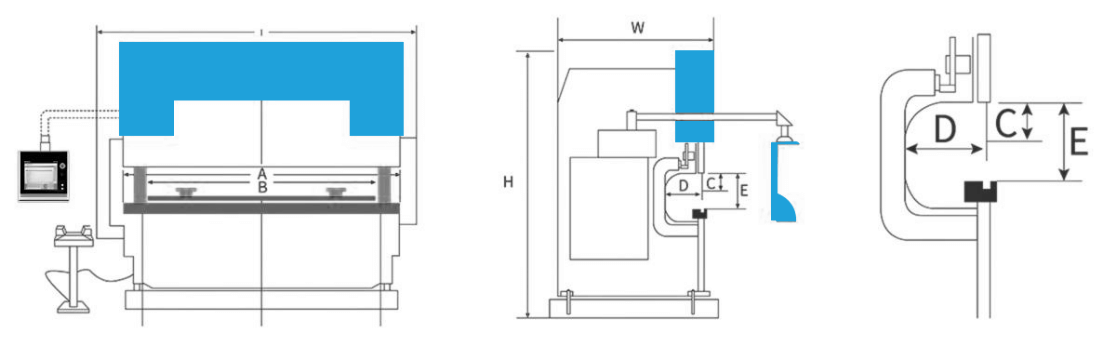

Frame design:

The GHT series represents the top of the range of press brakes produced by G-Press as they are characterized by advanced technological solutions deriving from previous experiences with an historic Italian partner.? It has a complete configuration that guarantees high speed and accuracy which can meet the bending requirements of the most demanding customers.

In order to ensure that the machine can still maintain good rigidity and accuracy after long time use, the structure has been designed considering 2.5 times the theoretical frame deformation inertia, and has passed the stress analysis and fatigue resistance test.

The unidirectional mechanical deflection compensation mechanism adopts a unique specially processed wedge block. Each set of wedge blocks is designed according to the deflection of the upper and lower beam. The CNC calculates the required compensation amount according to the load force when the workpiece is bent, and automatically controls the relative movement of the wedge block to effectively compensate for deflection. The mechanical compensation system, as well as the hydraulic one, is certainly a great help for the operator during bending operation; it is reliable, precise and is not subject to any oil leakage.

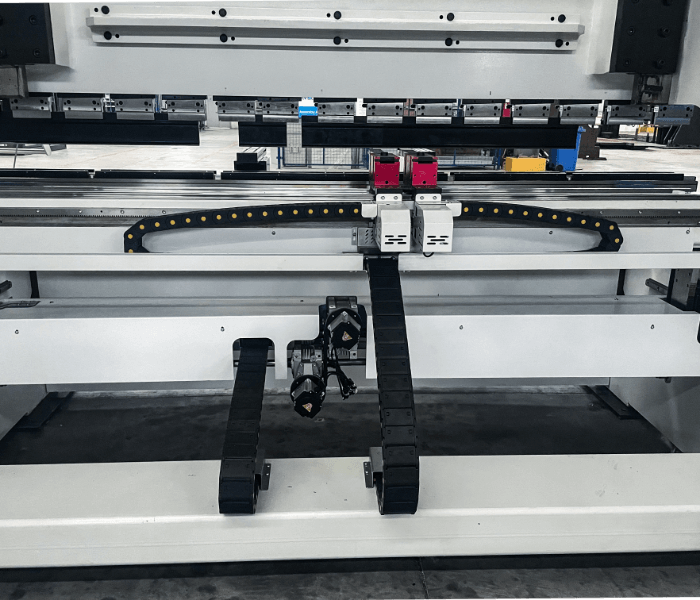

The back gauge system is another important part of the press brake as a guarantee of dimensional accuracy of the bending product. The 4 axes (X-R-Z1-Z2) back gauge of the standard GHT series ensures the most flexible, precise and high-speed positioning of almost all complex bending work pieces, thanks to the guide design which foresees the use of double sliders to ensure the accuracy.

The X-R axes motion is controlled by a double gear reducer system which is considered a “smart” design and has allowed to make a more compact version.

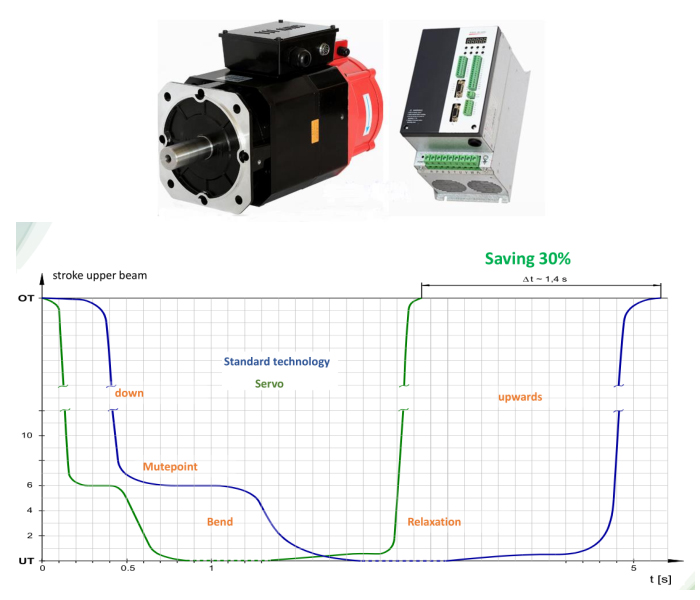

The motor offer excellent acceleration and are ideally suited for high speed and precision press brakes:

● High feed smoothness

● Large torque range

● High maximum speed

● High-resolution encoder

Benefits:

● High travel speed in the downward and backward movement

● High energy savings

● Longer service life for pump, oil, filter and all related components

Path-time diagram of the upper cylinder of a press brake.

The Netherlands DELEM CNC control features the following characteristics:

● 2D and 3D graphical touch screen programming;

● 3D visualisation in simulation and production;

● 17” high resolution color TFT;

● Full windows application suite;

● Bend sequence calculation;

● USB, peripheral interfacing;

● Open system architecture;

● Sensor bending & correction interface

HAWE hydraulic system: the hydraulic control system of the bending machine is composed of a SAKB pressure control block and two independent filling valves to ensure accurate and efficient operation of the CNC bending machine. All valves (except the filling valve) are integrated into one control unit. The bending force flow is controlled by proportional technology. In this way, the operating speed (approaching, working and returning) and the required pressure can be controlled.

※ Applicable to models with bending force up to 2000KN.

※ PIH and PSH valves provide very fast and accurate control by simultaneously energizing the solenoid coils at both ends of the solenoid valve.

※ Other options (such as hydraulic clamping module or proportional hydraulic deflection compensation) can be connected to the hydraulic system module interface.

※ Real-time tracking of the current position of the back gauge finger when bending.

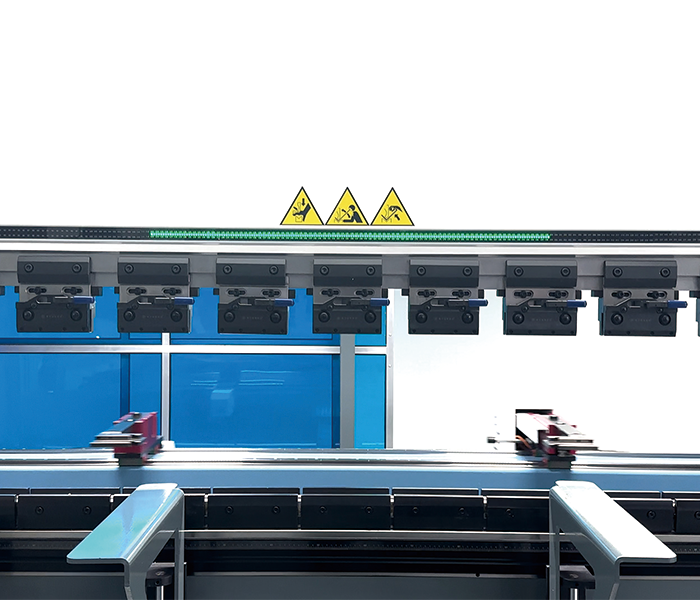

※ The LED light strip on the top beam indicates the actual position of the “back gauge finger” allowing the operator to quickly align the workpiece during the bending process, thus improving bending efficiency

※ The LED light strip provides warning and protection signs by changing color according to the three press brake working conditions: approaching speed (yellow LED light), working mode (red LED light) and return (green LED light).

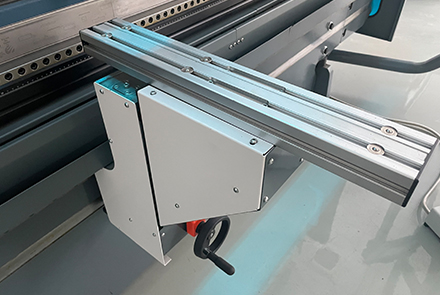

Manual sliding front support arms.

available for GHT and GHL series

G-Press foot pedal is in accordance to CE safety requirements; its features are as follows:

● Double safety switch which allows machine descent only if foot is totally inside

the pedal;

● 3-position safety design

● With shielded snake skin hose cable

Main Technical Features:

● Laser protection, Multi beam Receiver

● Protective areas: Front, middle and rear

● The safety level is CAT.4 and SIL3

● Detection Case protection degree: IP 65

● Laser classification: class 1 M

● Response time: 5 ms

● Operating temperature 0°C~50°C

● Mounted on the upper beam

● Change Speed Point: 5mm + Stopping Space

● The maximum protective distance: 15M

● LED indicators show various states

Consists of light guards mounted to the side frame which stops the machine if a human steps inside.

G-PLC is a safety module developed by our company. Downstream and upstream dual channel mode is used to ensure machine safety; it also integrates the upper and lower fixtures, ordinary light barriers, dual pedal interface and it can be expanded for more functions.

The indicators on the module provide great convenience for maintenance. It is equipped with an interface that allows direct communication with the software to locate the fault quickly and intuitively reduce downtime.

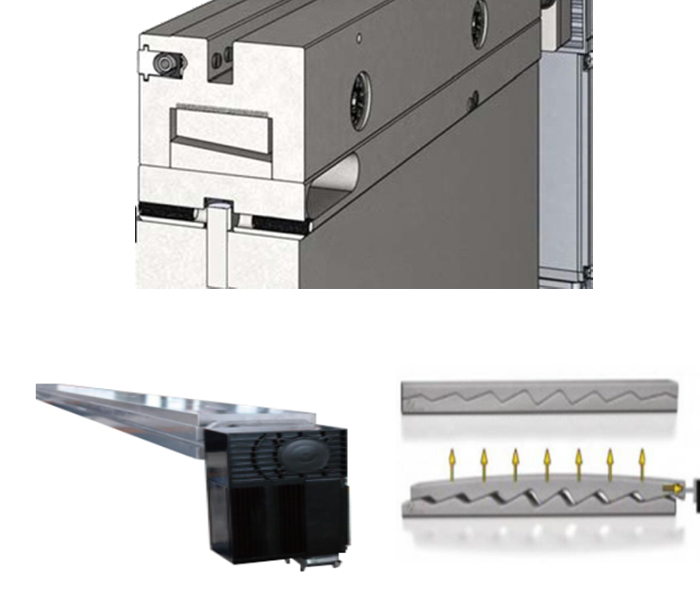

Standard intermediate clamp with quick release lever for fast tool change. Suitable for vertical loading/unloading of tools. No need to slide the tools laterally.

夾具.png)

Intermediate pneumatic and self aligning clamps.For quick tooling set up and release on machine.No risk of any oil leakage.