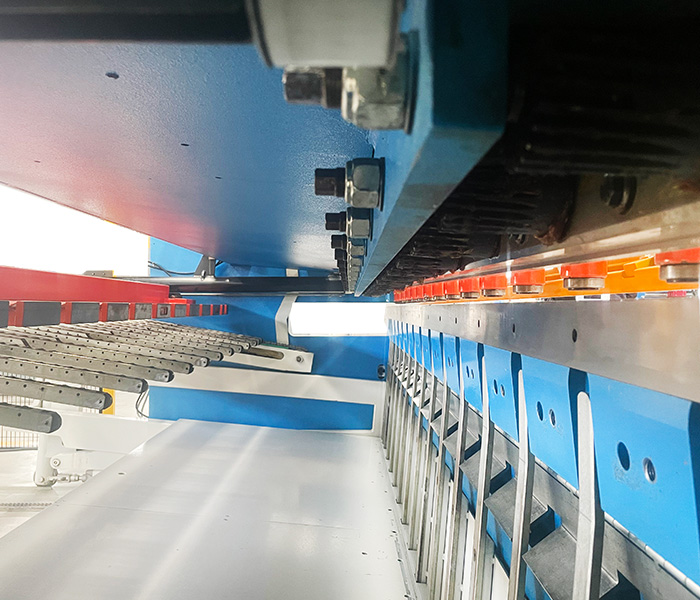

The electronic front ruler positioning device can ensure verticality with the cutting blade.

One key can start the machine no need manual operate anymore.

The pressure can be adjusted according to the thickness and strength of the material, and each pressing oil cylinder is equipped with anti indentation rubber pads at the bottom.

The blade gap automatic adjustment system is adjusted to 2.0mm;

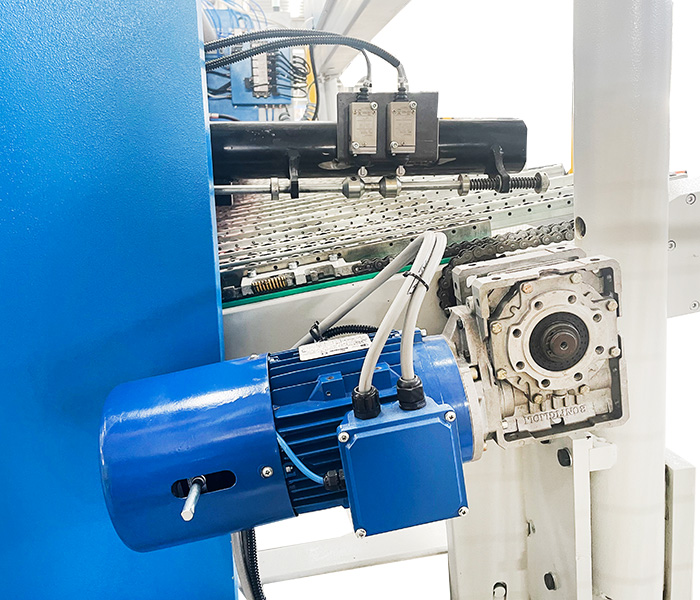

-Automatic adjustment of blade clearance (worm weel and worm gear device);

-Accurate adjustment of blade gap to ensure 0.05mm/M (gear adjustment device);

-Adjustable rear stopper, Max.stroke up to 1000mm

-The rear material blocking device and the knife holder are independent structures

-The transmission mode is servo motor directly driving the belt

Facilitate neat stacking of workpieces.

To avoid damage to the board caused by excessive height drop

Cutting positioning and supporting finished products,

Prepare for the subsequent rear fork frame.

Take the cut finished product to the back of the machine,

Flip down and let the finished product fall into the car along the rollers on the rear fork frame

Cut the waste and place it in the waste bin.

After the cutting and automatic stacking are completed, the cart can be automatically removed without the need for manual stacking.

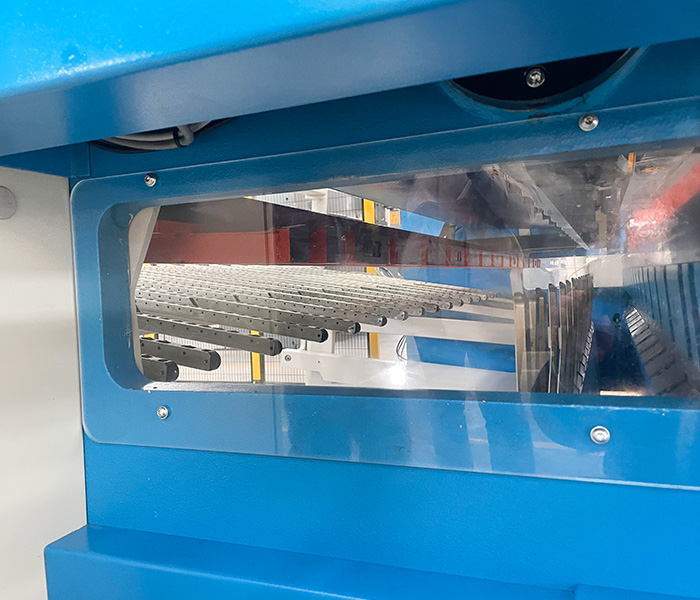

Prevent accidental entry and protect personal safety.

Your Name *

Your Email *

Your Phone

Your Products *

Message *

Your email information is completely secure and will not be disclosed to third parties for any reason.